<strike id="y6gek"></strike>

HOT NEWS

|

|

|

|

|

|

|

Related Products

Power plant general contracting

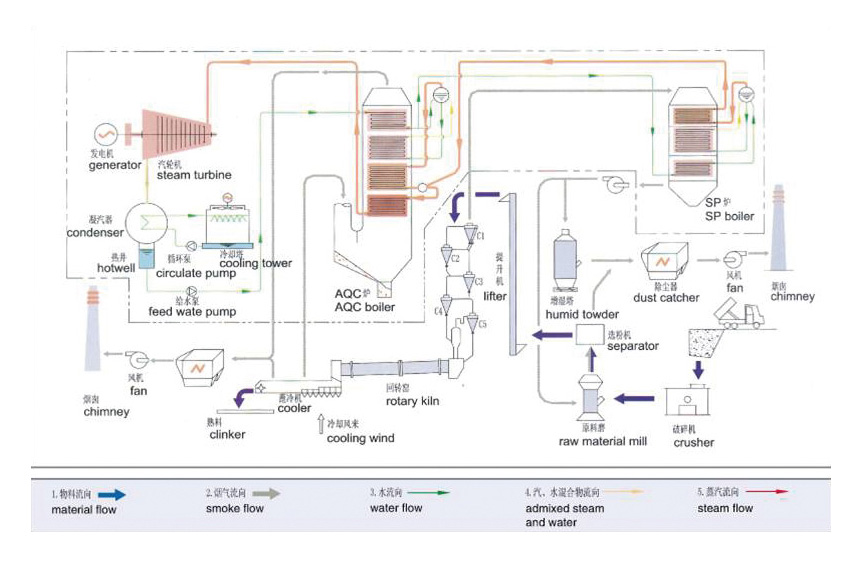

Cement kiln water heat power generation engineering

Nonferrous metals smelting and mineheating stovewaste heat generation engineering

Dry coke and coking gas waste heat generation engineering

Sintering, converter, electric furnace power generation engineering

Glasses kiln waste heat generation engineering